Perkins2306A(C)-E14發(fā)動(dòng)機(jī)故障維修診斷手冊(cè)

詳細(xì)描述

Perkins 2300 Series

Models 2306A-E14 and 2306C-E14

DIAGNOSTIC MANUAL

6 cylinder turbocharged diesel engine

Publication TSD 3457E, Issue 2.

© Proprietary information of Perkins Engines Company Limited, all rights reserved.

The information is correct at the time of print.

Published in December 2006 by Technical Publications,

Perkins Engines Company Limited, Peterborough PE1 5NA England.

Diagnostic Manual, TSD 3457E, Issue 2

i

This document is printed from SPI². Not for RESALE

![]()

![]()

Chapters

1 General information

2 Electronic system overview

3 Programming parameters

4 Fault diagnosis

5 Special Tools

The following pages contain a detailed table of contents

ii

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

Contents

1 General information

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1

Safety precautions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 2

Glossary of terms . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...3

2 Electronic system overview

System operation .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9

Electronic controls ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 9

Engine governor ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9

Timing considerations .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9

Fuel injection . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .10

Engine monitoring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .11

Fuel temperature monitoring ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .11

Self diagnostics ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .11

Effect of diagnostic codes on engine performance .. ... ... ... ... ... ... ... ... ... ... ... ... .12

Current totals stored in the ECM . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .12

Programmable parameters .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .12

Passwords . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .13

Diagnostic Manual, TSD 3457E, Issue 2

iii

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

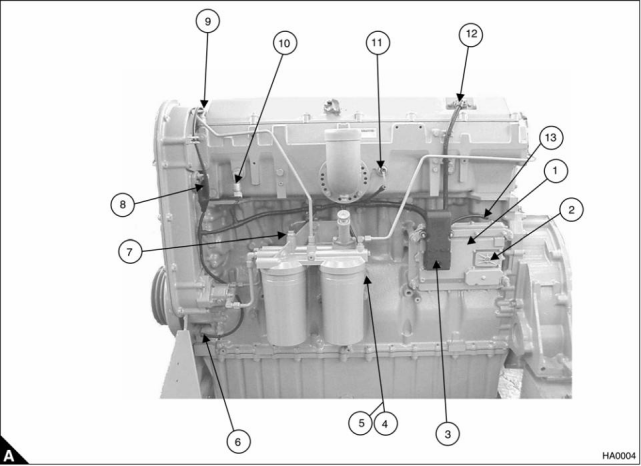

Engine component diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 14

OEM connection diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 15

Sensor and connector location diagram . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 16

Engine wiring diagram .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 17

Machine wiring diagram (all options) .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 18

Electrical connectors and functions ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Colour codes .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 19

Service tools and diagnostics .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 20

3 Programming parameters

Connecting the TIPSS-EST ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 21

Passwords .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 23

Programming a new ECM . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 24

Programming an ECM using flash programming ... ... ... ... ... ... ... ... ... ... ... ... ... ... 27

ECM date/time clock .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 28

ECM diagnostic clock ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

Injector codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

TIPSS-EST cylinder cut-out test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

Programming parameters . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 29

System configuration parameters ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 30

Customer specified parameters ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 32

4 Fault diagnosis

Introduction ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 35

Diagnostic procedures without a diagnostic fault code

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 36

iv

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

Diagnostic symptoms

Test 1 - Engine will not crank ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .37

Test 2 - Engine cranks but will not start ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .38

Test 3 - Engine misfires, runs rough or is unstable ... ... ... ... ... ... ... ... ... ... ... ... ... ... .39

Test 4 - Low power/poor or no response to throttle ... ... ... ... ... ... ... ... ... ... ... ... ... ... .40

Test 5 - Intermittent engine shutdowns . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .41

Test 6 - Intermittent low power or power cut-outs . ... ... ... ... ... ... ... ... ... ... ... ... ... ... .42

Test 7 - Electronic service tool will not communicate with the ECM . ... ... ... ... ... ... ... .43

Test 8 - ECM will not accept factory passwords ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .44

Test 9 - Excessive black smoke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .45

Test 10 - Excessive white smoke .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .46

Test 11 - Excessive blue smoke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .47

Test 12 - Engine cannot reach correct rev/min . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .48

Test 13 - Poor acceleration or response ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .49

Test 14 - Poor fuel consumption ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .50

Test 15 - Too much vibration . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .51

Test 16 - Noise coming from cylinder ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .52

Test 17 - Excessive valve clearance . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .53

Test 18 - Valve rotocoil or spring lock is free ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .54

Test 19 - Mechanical noise (knock) in engine ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .55

Test 20 - Oil in cooling system .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .56

Test 21 - Fuel in cooling system ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .57

Test 22 - Coolant in lubricating oil . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .58

Test 23 - Fuel dilution of lubricating oil .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .59

Test 24 - Engine has early wear ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .60

Test 25 - Engine has low oil pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .61

Test 26 - Engine uses too much lubricating oil .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .62

Test 27 - Engine coolant is too hot ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .63

Test 28 - Oil at the exhaust ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .64

Test 29 - Engine has a fuel supply problem .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .65

Test 30 - Indicator lamp not functioning correctly .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .66

Test 31 - Inlet air manifold temperature is too high ... ... ... ... ... ... ... ... ... ... ... ... ... ... .67

Test 32 - Engine has a high fuel temperature ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .68

Diagnostic procedures with an event code

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .69

Event codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .69

Diagnostic tests

Test 33 - High intake manifold pressure ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .70

Test 34 - Low oil pressure . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .71

Test 35 - High coolant temperature ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .72

Test 36 - Engine overspeed .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .73

Test 37 - High fuel temperature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .74

Test 38 - High intake manifold air temperature . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .75

Diagnostic Manual, TSD 3457E, Issue 2

v

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

Diagnostic procedures with a diagnostic fault code

General information .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 76

Diagnostic codes ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 76

Diagnostic terminology . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 78

Connectors . ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 79

Diagnostic tests

Test 39 - Inspecting electrical connectors .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 82

Test 40 - Electrical power supply to the ECM ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 88

Test 41 - Analogue sensor open or short circuit test . ... ... ... ... ... ... ... ... ... ... ... ... ... 91

Test 42 - ECM Status indicator output circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... .. 101

Test 43 - +5 V Sensor voltage supply circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 107

Test 44 - PWM desired speed setting circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 112

Test 45 - Perkins Data Link circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 118

Test 46 - Engine speed/timing circuit test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 126

Test 47 - Engine speed/timing calibration .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 134

Test 48 - Injector solenoids circuit test ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 138

Test 49 - Analogue sensor abnormal test .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 146

5 Special tools

Required service tools .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 149

Optional service tools ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 150

vi

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

1

General information

1

Introduction

The 2300 and 2800 Series industrial diesel engines are the latest development from Perkins Engines

Company Limited, a world leader in the design and manufacture of high performance diesel engines.

Read and remember the "Safety precautions" on page 2. They are given for your protection and must be

applied at all times.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible danger to the person.

Caution: This indicates that there is a possible danger to the engine.

Note: Is used where the information is important, but there is not a danger.

Ensure that all adjustments and repairs are done by personnel who have had the correct training.

Diagnostic Manual, TSD 3457E, Issue 2

1

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

Safety precautions

These safety precautions are important. Reference must also be made to the local regulations in the country

of operation.

Only use these engines in the type of application for which they have been designed.

Do not change the specification of the engine.

Do not smoke when you put fuel in the tank.

Clean away fuel which has been spilt. Material which has been contaminated by fuel must be moved to a

safe place.

Do not put fuel in the tank while the engine runs (unless it is absolutely necessary).

Do not clean, add lubricating oil, or adjust the engine while it runs (unless you have had the correct training;

even then extreme caution must be used to prevent injury).

Do not make adjustments that you do not understand.

Ensure that the engine does not run in a location where it can cause a concentration of toxic emissions.

Other persons must be kept at a safe distance while the engine or equipment is in operation.

Do not permit loose clothing or long hair near moving parts.

Keep away from moving parts during engine operation.

Warning! Some moving parts cannot be seen clearly while the engine runs.

Do not operate the engine if a safety guard has been removed.

Do not remove the filler cap of the cooling system while the engine is hot and while the coolant is under

pressure, because dangerous hot coolant can be discharged.

Do not use salt water or any other coolant which can cause corrosion in the closed coolant circuit.

Do not allow sparks or fire near the batteries (especially when the batteries are on charge) because the

gases from the electrolyte are highly flammable. The battery fluid is dangerous to the skin and especially

to the eyes.

Disconnect the battery terminals before a repair is made to the electrical system. Always disconnect the

negative terminal first.

Only one person must control the engine.

Ensure that the engine is operated only from the control panel or from the operator’s position.

If your skin comes into contact with high-pressure fuel, obtain medical assistance immediately.

Diesel fuel and lubricating oil (especially used lubricating oil) can damage the skin of certain persons.

Protect your hands with gloves or a special solution to protect the skin.

Do not wear clothing which is contaminated by lubricating oil. Do not put material which is contaminated

with oil into the pockets.

Discard used lubricating oil in a safe place to prevent contamination.

The combustible material of some components of the engine (for example certain seals) can become

extremely dangerous if it is burned. Never allow this burnt material to come into contact with the skin or with

the eyes.

Fuel and oil pipes MUST be inspected for cracks or damage before they are fitted to the engine.

Fit only genuine Perkins parts.

2

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

1

2300 Series

Glossary of terms

Active diagnostic code

Describes a condition that is currently present to alert the operator or service technician of an abnormal engine

operation parameter. See also Diagnostic fault code.

Aftermarket device

A device or an accessory that is installed by the customer or OEM after the engine has been delivered.

Alternating current (AC)

The direction of current flow changes (alternates) regularly and constantly in a circuit.

Atmospheric pressure sensor

Analogue sensor generates a signal proportional to atmospheric (barometric) air pressure in the crankcase

and sends a signal to the ECM.

Before top center (BTC)

The 180° of crankshaft rotation before the piston reaches the very top of its travel (normal direction of rotation).

Intake manifold pressure sensor

This sensor measures inlet manifold air pressure (boost pressure) and sends a signal to the ECM.

Bypass circuit

A circuit, usually temporary, to substitute for an existing circuit, typically for test purposes.

Calibration

An electronic adjustment of a sensor signal.

Perkins engine monitoring

The part of the Perkins Electronic Engine Control that monitors coolant temperature, oil pressure, intake

manifold air temperature and coolant level to alert the operator of detected problems. The coolant temperature,

intake manifold air temperature, and oil pressure sensors are supplied by Perkins and monitored by the ECM.

Aftermarket engine monitoring systems do not interface with the Perkins Electronic Engine Control.

Check engine lamp

Sometimes referred to as the diagnostic lamp, it is used to alert the operator of the presence of an active event.

Code

Refer to diagnostic fault code and diagnostic event code.

Cold mode

A mode of engine operation where the timing is retarded for engine protection, reduced smoke emissions and

faster warm up time.

Diagnostic Manual, TSD 3457E, Issue 2

3

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

Component identifier (CID)

The CID is a number that identifies the specific component of the electronic control system that has

experienced a diagnostic code. This is part of the PDL (Perkins Data Link).

Communication adapter

The communication adapter provides a communication link between the ECM and an electronic service tool.

Coolant temperature sensor

This sensor detects the engine coolant temperature for Cold Mode operation and Perkins Engine Monitoring.

Crankshaft position sensor

A sensor that measures the crankshaft position, the direction of rotation, and engine rev/min and sends signals

to the ECM.

Customer specified parameter

A parameter value that can be changed and whose value is set by the customer. These parameters can be

protected by customer passwords.

Desired rev/min

An input to the electronic governor in the ECM. The electronic governor uses inputs from the crankshaft

position sensor and customer parameters to determine 'desired rev/min'.

Diagnostic event code

These codes indicate an event that describes an abnormal engine condition such as a shutdown occurrence.

These codes are not necessarily (or usually) an indication of problems within the electronic system.

Diagnostic fault code

Sometimes referred to as a "fault code". These codes indicate an electronic system malfunction or problem

with the engine electronic system.

Diagnostic lamp

Sometimes referred to as the "engine check lamp", it is used to alert the operator of the presence of an active

diagnostic code.

Direct current (DC)

The type of current where the direction of current flow is consistently in one direction.

Duty cycle

Refer to pulse width modulation.

Engine control module (ECM)

The engine control computer that provides power to the engine electronics. It accepts inputs that monitor and

outputs that control or change to act as a governor to control engine rev/min.

Electronically controlled unit injector

The injection pump which is a mechanically actuated, electronically controlled unit injector, combining the

pumping, electronic fuel metering and injecting elements in a single unit.

Electronic engine control

The complete electronic system that monitors and controls the engine operation under all conditions.

Engine speed/timing sensor

Provides a variable amplitude and pulse width modulated signal to the ECM, which the ECM interprets as

crankshaft position and engine speed.

Estimated dynamic timing

The ECM's estimation of actual injection timing.

4

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

Failure mode identifier (FMI)

Type of failure that has been experienced by the component (adopted from the SAE standard practice of J1587

diagnostics).

Flash programming

A method of programming or updating an ECM with an electronic service tool over the data link instead of

replacing components.

Fuel position

An internal signal within the ECM, from the electronic governor to the fuel injection control. It is based on

desired rev/min, FRC fuel limit, rated fuel limit, and the actual engine rev/min.

Fuel ratio control (FRC)

A limit based on control of the fuel to air ratio and used for emission control purposes. When the ECM senses

a higher intake manifold pressure (more air into cylinder), it increases the FRC fuel limit (allows more fuel into

cylinder).

Fuel temperature sensor

This sensor detects the fuel temperature. The ECM monitors the fuel temperature and adjusts the calculated

fuel rate accordingly.

Full load setting (FLS)

Number representing fuel system adjustment made at the factory to "fine tune" the fuel system maximum fuel

delivery. Correct value for this parameter is stamped on the engine information ratings plate. This parameter

must be programmed or a 268-02 Check Programmable Parameters diagnostic code will be generated.

Full torque setting (FTS)

Similar to the Full Load Setting. This parameter must be programmed or a 268-02 Check Programmable

Parameters diagnostic code will be generated.

Harness

The wiring loom that connects all components of the electronic system.

Hertz (Hz)

Measure of electrical frequency in cycles per second.

Diagnostic Manual, TSD 3457E, Issue 2

5

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

Histogram

A bar graph indicating the relative frequency of engine operation in specific operating ranges.

Injector codes

Four digit code etched on the tappet or stamped on individual injectors of the electronic unit injectors.

Intake manifold air temperature sensor

This sensor detects the intake manifold air temperature. The ECM monitors the inlet air temperature and

coolant temperature to adjust injection timing.

Integrated electronic controls

The engine is designed with the electronic controls as a necessary part of the system. The engine will not

operate without the electronic controls.

J1939 data link

An SAE (Society of Automotive Engineers) standard data link used to communicate between the electronic

engine, the transmission, and/or powertrain controls.

Logged diagnostic codes

Describes codes which are stored in memory. These codes are meant to be an indicator of possible causes

for intermittent problems. Refer to diagnostic fault code.

Oil pressure sensor

This sensor measures engine oil pressure and sends a signal to the ECM as part of Perkins Engine Monitoring.

Open circuit

Condition where an electrical wire or connection is broken or a switch is open, so that the signal or the supply

voltage can no longer reach its intended destination.

Original equipment manufacturer (OEM)

The manufacturer of equipment in which a Perkins engine is installed.

Parameter

A programmable value or limit which determines the characteristics or behaviour of the engine.

Parameter identifier (PID)

Two or three digit code which is assigned to each component in order to identify data via the data link to the

ECM.

Password

A group of numeric or alphanumeric characters that is designed to restrict access to parameters. The

electronic system requires correct passwords in order to change customer specified parameters (customer

passwords) or certain engine specifications (factory passwords). Passwords are also required to clear certain

diagnostic codes.

6

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

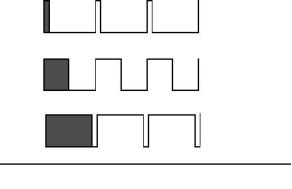

Pulse width modulation (PWM)

A signal consisting of variable width pulses at fixed intervals, whose ratio of "TIME ON" versus total "TIME

OFF" can be varied (also referred to as "duty cycle").

ON

10% Duty Cycle

OFF

ON

50% Duty Cycle

OFF

ON

90% Duty Cycle

OFF

TIME

Example of Pulse Width Modulation (PWM) Signals

Rated fuel limit

Indicates the maximum allowable fuel position (longest injection pulse). It will produce rated power for this

engine configuration.

Reference voltage

A regulated, unchanging voltage supplied by the ECM to a sensor. The reference voltage is used by the sensor

to generate a signal voltage.

Sensor

A device that is used to detect and convert a change in pressure, temperature, or mechanical movement into

an electrical signal.

Short circuit

A condition where an electrical circuit is unintentionally connected to an undesirable point. An example of a

short circuit is a wire which rubs against an engine frame until it eventually wears off its insulation and makes

electrical contact with the frame.

Subsystem

A part of the electronic system that relates to a particular function.

Supply voltage

A constant voltage supplied to a component to provide electrical power for its operation. It may be generated

by the ECM or may be battery voltage supplied by the equipment wiring.

System configuration parameters

Parameters that affect the power rating family or emissions.

"T" harness

A test harness that is designed to connect into the engine harness which allows normal circuit operation while

providing a breakout or "T" in order to measure signals.

Timing calibration

The adjustment of an electrical signal as a means of correcting the timing error between the crankshaft and

crankshaft position sensors.

Diagnostic Manual, TSD 3457E, Issue 2

7

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

1

2300 Series

TIPSS-EST

A service tool software program to run on a personal computer (PC).

Total tattletale

Total number of changes to all the customer specified parameters stored in the ECM.

8

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2300 Series

2

Electronic system overview

2

System operation

The 2300 and 2800 Series industrial diesel engines are designed for electronic control. The injection pump,

fuel lines and nozzles used in mechanical engines have been replaced with an electronic unit injector in each

cylinder. A solenoid on each injector controls the amount of fuel that is delivered by the injector. An Engine

Control Module (ECM) sends a signal to each injector solenoid in order to provide complete control of the

engine.

Electronic controls

The electronic system consists of the Engine Control Module (ECM), the engine sensors and the OEM

interface. The ECM is the computer which controls the engine and contains the software which controls how

the ECM behaves and stores the operating maps that define power, rev/min, etc.

Engine governor

The electronic controls on the engine serve as the engine governor, determining when and how much fuel to

deliver to the cylinders based on the actual and desired conditions at any given time.

The ECM uses one of three possible speed control inputs to determine the desired engine speed and

compares this to the actual engine speed determined through the crankshaft position sensor. If the desired

engine speed is greater than the actual engine speed, more fuel is injected in order to increase engine speed.

Timing considerations

Once the ECM has determined how much fuel is required, it must next determine when to inject the fuel.

Injection timing is determined by the ECM after considering input from the following components:

Coolant temperature sensor

Intake manifold air temperature sensor

Atmospheric pressure sensor

Intake manifold pressure sensor

The ECM determines where top centre on cylinder number one is located from the engine camshaft position

sensor signal. The ECM decides when injection should occur relative to top centre and provides the signal to

the injector at the desired time. The ECM adjusts timing for the best engine performance, fuel economy and

white smoke control.

Note: Actual or desired timing cannot be viewed with the TIPSS-EST service tool.

Diagnostic Manual, TSD 3457E, Issue 2

9

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

2

2300 Series

Fuel injection

The ECM controls the amount of fuel injected by varying the signals to the injectors. The injectors will pump

fuel only if the injector solenoid is energized. The ECM sends a high voltage signal to energize the solenoid.

By controlling the timing and duration of the high voltage signal the ECM can control injection timing and the

amount of fuel that is injected.

The software inside the ECM sets certain limits on the amount of fuel that can be injected. The fuel limit is a

limit based on boost pressure to control the air/fuel ratio for control of emissions. When the ECM senses a

higher boost pressure (more air into cylinder) it increases the fuel limit (allows more fuel into cylinder).

The Rated Fuel Limit is a limit that is based on the power rating of the engine and engine rev/min. It is similar

to the rack stops and torque spring on a mechanically governed engine. It provides power and torque curves

for a specific engine family and rating.

Note: All of these limits are determined at the factory in the ECM software and cannot be changed.

10

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Engine monitoring

Perkins provides a factory installed engine monitoring system. The Perkins engine monitoring system monitors

the following parameters:

Engine oil pressure

Coolant temperature

Intake manifold air temperature

Engine speed

Boost pressure

Fuel temperature

The Perkins engine monitoring system has three levels of operation, WARNING, ACTION ALERT and

SHUTDOWN as described below.

Perkins engine monitoring WARNING operation

In the WARNING condition the ECM causes the Warning lamp to turn ON to indicate a problem has been

detected by the Engine Monitoring System. No further ECM or engine action occurs.

Perkins engine monitoring ACTION ALERT operation

In the ACTION ALERT condition the ECM begins by activating the Action Alert lamp ON to indicate a problem

has been detected by the Engine Monitoring System. This is also normally wired to cause a shutdown via the

OEM control panel.

Perkins engine monitoring SHUTDOWN operation

If the fault reaches the SHUTDOWN condition the ECM activates the shutdown lamp and unless the engine is

in CRITICAL OVERRIDE condition, the engine will shutdown.

Fuel temperature monitoring

The fuel temperature sensor monitors the fuel temperature, adjusting the ECM calculated fuel rate to

compensate for fuel temperature changes and to adjust the fuel rate for constant power. The sensor is also

used to warn the operator of excessive fuel temperature with a diagnostic event code because excessive fuel

temperatures can adversely affect engine performance.

Self diagnostics

The electronic system has the ability to diagnose problems. When a problem is detected, a diagnostic code is

generated and stored in permanent memory (logged) in the ECM. The diagnostic lamp is also activated.

When diagnostic codes occur, the diagnostic codes are referred to as Active diagnostic codes. They indicate

that a problem of some kind currently exists.

Diagnostic codes that are stored in memory are called Logged diagnostic codes. Since the problem may have

been temporary, or may have been repaired since the problem was logged, logged codes do not necessarily

mean that something needs to be repaired. They are instead meant to be an indication of probable causes for

intermittent problems.

Diagnostic codes that identify operating conditions outside the normal operating range are called Events.

Event codes are not typically an indication of an electronic system problem.

Note: Some of the diagnostic codes require passwords to clear.

Diagnostic Manual, TSD 3457E, Issue 2

11

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

2

2300 Series

Effect of diagnostic codes on engine performance

The discussion on engine monitoring mentions that the diagnostic lamp activates when a specific condition

exists. When the ECM detects an engine problem, it generates an active diagnostic code and also logs the

diagnostic code in order to indicate when, and if appropriate, how many times the problem occurred. There are

two types of diagnostic codes, Fault codes and Event codes.

Diagnostic fault codes

These are provided in order to indicate that an electrical or electronic problem has been detected by the ECM.

In some cases the engine performance can be affected when the condition causing the code exists. More

frequently, however, no difference in the engine performance can be detected.

Diagnostic event codes

Diagnostic event codes are used to indicate that some operational problem has been detected in the engine

by the ECM. This usually does not indicate an electronic malfunction.

The ECM also provides an ECM clock with date/time to date and time stamp the following critical event codes:

360-3 Low oil pressure Shutdown

361-3 High coolant temperature Shutdown

For a listing all of the diagnostic fault codes, along with the page number where details regarding the cause,

performance effect, and diagnosis of the code can be located, refer to "Diagnostic code quick reference" on

page 80.

Current totals stored in the ECM

The ECM maintains engine total data for the following parameters:

Total time

The total time is the engine's operating hours. This does not include operating time when the ECM is powered

ON but the engine is not running.

Programmable parameters

Certain parameters affecting engine operation may be changed with the TIPSS-EST service tool. The

parameters are stored in the ECM, and are protected from unauthorized changes by passwords. These

parameters are either system configuration parameters or customer parameters.

System configuration parameters

These are set at the factory and affect emissions or power ratings within an engine family. Factory passwords

must be obtained and used to change the system configuration parameters.

Customer parameters

These are variable and can be used to tailor the engine to customer requirements within the limits set by the

factory and Perkins engine monitoring operation. Customer passwords may be required to change customer

parameters.

Caution: Some of the parameters may affect engine operation. Without adequate training, these parameters

may lead to power or performance complaints even when the engine is performing to specification.

Refer to "Programming parameters" on page 29 for further information.

12

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

2

2300 Series

Passwords

System configuration parameters are protected by factory passwords. Factory passwords are calculated on a

computer system that is available only to Perkins dealers.

Customer parameters can be protected by customer passwords. The customer passwords are programmed

by the customer. Factory passwords can be used to change customer passwords if they are lost.

Refer to "System configuration parameters" on page 30 for further information when passwords are needed

and how to obtain them.

Diagnostic Manual, TSD 3457E, Issue 2

13

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Engine component diagram

Internal Injector Harness

12PIN Connector

Service

Tool

Connector

Interface

Connector

OEM Interface Connectors

Main Engine Harness

Crank Speed/Timing

Cam Speed/Timing

36-1 TOOTH

CRANK

GEAR

Inlet Manifold Temperature

Sensor

Fuel Temperature Sensor

36+1 TOOTH

CAM GEAR

Cooolat Temperature Sensor

Atmospheric Pressure Sensor

Boost

Pres Sensor

Calibration

Probe

Lub Oil Pressure

Sensor

A

HA0002

14

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

OEM connection diagram

To ECM J1 Connector

Customer connecter (If fitted)

E-Stop

16A Breaker

Service Tool

Connector

Keyswitch

Injector D, isable

Optional

24V

Digital Speed Control

Optional

Optional

Speed

Raise/Lower

Critical Override

Optional

Optional

Throttle Adjust Pot

Lamp Box

1: Diagnostics

2: Caution

3: Warning

Speed Control

4: Shutdown

5: Overspeed

6: High Coolant Temp

7: Low Pressure

1

2

3

Shutdown

Reset

Optional

droop

adjust

-B

S

D

+B

Switched

Battery +ve

Optional

Droop/Isoch

Optional

Potentiometer

0.5-4.5V

Speed

Selection

Optional

Screen tied to

ECM -VE

A

HA0003

Diagnostic Manual, TSD 3457E, Issue 2

15

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Sensor and connector location diagram

1 Electronic Control Module (ECM)

2 J1/P1 Machine connector

3 J2/P2 Engine connector

4 Atmospheric pressure sensor

5 Oil pressure sensor

6 Crankshaft position sensor

7 Fuel temperature sensor

8 Camshaft position sensor

9 Coolant temperature sensor

10 Intake manifold pressure sensor

11 Intake manifold air temperature sensor

12 Electronic unit injector connector

13 Timing calibration pickup connector

16

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Engine wiring diagram

ECM

5

7

6

J2/44

J2/45

J2/46

J2/55

J2/54

J2/39

J2/38

J2/37

J2/36

Injector Common Cylinders 1 & 2

Injector Common Cylinders 3 & 4

Injector Common Cylinders 5 & 6

Injector Cylinder 6

Injector Cylinder 5

Injector Cylinder 4

Injector Cylinder 3

Injector Cylinder 2

Injector Cylinder 1

B

B

B

A

P

G

W

B

B

B

A

P

G

W

K

10

3

11

2

12

1

K

R

R

Injector

Cyl 1

Injector

Cyl 2

Injector

Cyl 3

Injector

Cyl 4

Injector

Cyl 5

Injector

Cyl 6

J300 P300

Atmospheric Pressure Sensor

+5V

Signal

Return

A

C

B

J2/2

J2/14

J2/3

+5VDC Supply

Atmospheric Pressure

Analogue Return

O

U

N

P203 J203

Intake Manifold Pressure Sensor

+5V

Signal

Return

A

C

B

Intake Manifold Pressure

J2/40

U

P200 J200

Oil Pressure Sensor

+5V

Signal

Return

A

C

B

J2/24

J2/32

J2/33

Oil Pressure

A

P201 J201

Coolant Temperature Sensor

Coolant Temperature

Signal

Return

C

B

U

J100 P100

Fuel Temperature Sensor

C

Fuel Temperature

Signal

Return

U

B

J105 P105

Inlet Air Temperature Sensor

Signal

Return

C

B

J2/35

J2/18

Inlet Air Temperature

Return

U

N

J103 P103

Crankshaft Position Sensor

Signal

Return

2

1

J2/48

J2/49

Crank Speed Timing +

Crank Speed Timing -

Y

U

J401 P401

Camshaft Position Sensor

Signal

Return

2

1

J2/58

J2/59

Cam Speed timing +

Cam speed timing -

Y

U

J402 P402

Calibration Probe

Signal

Return

1

2

J2/22

J2/23

Calibration Probe +

Calibration Probe -

Y

U

J400 P400

P2 J2

A

HA0005

Diagnostic Manual, TSD 3457E, Issue 2

17

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Machine wiring diagram (all options)

This Wiring Supplied By OEM

Outputs may be used to

drive lamps or relays

Customer

Interface

Connector

J3 P3

11

ECM

Engine Running

Shutdown

Engine Running Output

J1/13

J1/10

W

G

16

5

Shutdown lamp Output

Action Alert Lamp Output

Warning Lamp Output

System Fault Lamp Output

Action Alert

J1/19

U

Warning

4

3

J1/20

J1/31

P

I

Diagnostics

Oil Pressure

8

J1/28

J1/29

Oil Pressure Lamp Output

O

N

Coolant Temp

17

Coolant Temperature Lamp Output

Overspeed Lamp Output

Overspeed

9

J1/30

J1/49

A

2

Digital Speed Control Enable

Injection Disable

Digital Speed

Control Enable

G

U

P

K

O

N

A

Y

34

J1/62

J1/59

Injection

Disable

29

35

Lower Speed

Lower

Speed

J1/64

J1/7

Shutdown Emergency Override

Raise Speed

Critical Override

28

Raise

Speed

25

26

18

12

J1/56

1500/1800 rpm Select

Droop/Isochronous

Fault Reset

1500/1800

rpm Select

J1/46

Droop/

Isochronous

J1/41

J1/18

Fault Reset

Digital Ground

- Battery

B

B

27

22

J1/67

J1/5

Ground

Ground

To PWM

Speed Control

(If Required)

B

PWM

36

21

J1/66

J1/4

PWM Input

+8V

W

R

+8V

23

20

680R

B

B

5K Analogue

Speed Setting

Potentiometer or

Input from Load

Sharer/Synchroniser

J1/3

Analogue Ground

Analogue Speed Input

+5V

24

19

38

J1/17

J1/2

W

R

B

680R

J1/61

J1/63

J1/65

J1/48

J1/52

J1/53

- Battery

- Battery

Charging

Alternator

39

B

- Battery

40

15

33

GRD

POS

B

Emergency

Stop Button

Unswitched + Battery

R

R

R

Unswitched + Battery

Unswitched + Battery

1

10

31

32

11

7

J1/70

J1/50

J1/34

J1/42

Switched + Battery

J1939 Data Link +

Key

Switch

Y

G

Circuit

Breaker

J1939

J1939 Data Link -

J1939 Screen

Data

Link

A

Starter

Motor

Perkins Data Link +

Perkins Data Link -

Perkins

Data

Link

J1/8

J1/9

G

6

Start

N

Button

J1/55

J1/69

Unswitched + Battery

- Battery

R

B

-

+

P1 J1

Battery

9 Pin Perkins Data

Link Connector

24V DC

J

H C G F

D E A B

A

HA0006

18

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Electrical connectors and functions

Connector

Function

J1/P1

ECM connector (70-Pin OEM harness)

J2/P2

ECM connector (70-Pin Engine harness)

J3/P3

Machine wiring connector (40-Pin connector) - optional

Engine coolant temperature sensor (2-pin connector)

Engine intake manifold temperature sensor (2-pin connector)

Engine fuel temperature sensor (2-pin connector)

Engine intake manifold pressure sensor (3-pin connector)

Engine oil pressure sensor (3-pin connector)

J100/P100

J103/P103

J105/P105

J200/P200

J201/P201

J203/P203

J300/P300

J400/P400

J401/P401

J402/P402

Engine atmospheric pressure sensor connector (3-pin connector)

Injector solenoid harness (12-pin connector)

Engine timing calibration probe (2-pin connector)

Crankshaft position sensor (2-pin connector)

Camshaft position sensor (2-pin connector)

Colour codes

Key letter

Colour

Brown

Blue

N

U

R

P

Red

Purple

Green

White

Yellow

Black

Orange

Pink

G

W

Y

B

O

K

A

Grey

Diagnostic Manual, TSD 3457E, Issue 2

19

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

2

2300 Series

Service tools and diagnostics

The Perkins TIPSS-EST service tool is designed to help the service technician analyse and locate faults or

problems within the system. They are required to perform calibrations and to read or change engine

parameters.

Perkins TIPSS-EST is a software program that runs on a personal computer and requires a communication

adapter to translate information from the Perkins Data Link to the computer RS232 port.

Perkins TIPSS-EST can be used to display the following information:

Programmable parameter settings

Active and logged diagnostic codes

Logged events

Engine rating history

Histograms

Custom data

ECM date/time clock

Perkins TIPSS-EST can also be used to perform the following functions:

Diagnostic tests

Sensor calibrations

Flash programming

Parameter programming

Copy configuration (ECM replacement)

Data logging

Real time graphing

There are several adapter cables, breakout T cables, etc that are used in order to access measurements of

signals. A heavy duty multimeter is suitable in order to make the necessary measurements. A multimeter that

has the ability to measure duty cycle may also be required. Other special tools include those needed to

measure pressure and temperature. For further details refer to Chapter 5, Special tools.

A diagnostic code reader is also available. This is a hand held unit which allows reading certain parameters

and diagnostic codes.

20

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

2300 Series

3

Programming parameters

3

Connecting the TIPSS-EST

The communications adapter is powered by 24 Volts DC from the engine battery. This permits operation

beside the engine to allow use during engine operation.

Use the following procedures to connect the service tool to the engine.

1 Stop the engine by turning the key switch to the OFF position.

2 Connect the service tool harness cable on the engine to the communication adapter. Refer "Connecting

TIPSS-EST using a TIPSS communication adapter" on page 22.

3 Connect the communication adapter to the PC using the appropriate cable.

4 Turn the key switch to the ON position in order to begin testing. The service tool will operate while the engine

is running or with the engine OFF and the key switch ON. If the tool does not communicate with the ECM

disconnect and reconnect the diagnostics connector cable. Check the communication. If the problem is still

present refer to Test 45: Perkins Data Link circuit test on page 118.

Notes:

The service tool may restart during engine cranking due to a voltage dip on the battery line.

The TIPSS-EST must be configured to communicate with the specific type of communication adapter used.

Go to the "Preferences" menu that is located under "Utilities" in order to select the appropriate

communication adapter.

Diagnostic Manual, TSD 3457E, Issue 2

21

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

3

2300 Series

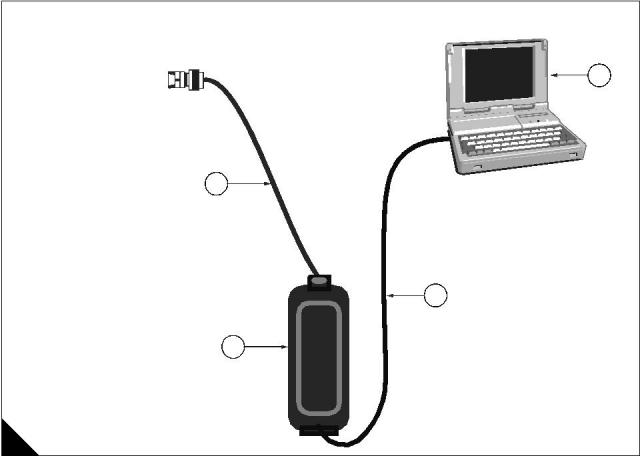

Connecting TIPSS-EST using a TIPSS communication adapter

1 PC with TIPSS-EST installed

2 PC to communication adapter cable (27610169)

3 Communication adapter (27610165)

4 Service tool harness cable (27610168)

1

4

2

3

A

HA0007

22

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

3

2300 Series

Passwords

Factory passwords

Factory passwords are required to perform each of the following functions:

1 Program a new ECM

When an ECM is replaced the system configuration parameters must be programmed into the new ECM. A

new ECM will allow these parameters to be programmed once without factory passwords. After the initial

programming these parameters are protected by factory passwords.

2 Rerate to another engine family

This requires changing the ECM software code, which is protected by factory passwords.

3 Read customer passwords

If the owner loses his customer passwords, he will not be able to program customer parameters. By using

factory passwords, one can read customer passwords, then use those customer passwords to program

customer parameters.

4 Clear certain diagnostic codes

Diagnostic code 253-02 Incorrect ECM software requires a factory password to clear the code. This diagnostic

code should be cleared only if you are certain that the ECM software is for the specific engine.

Caution: Operating the engine with ECM software not designed for that engine will result in engine damage.

Be sure the ECM software is correct for your engine.

5 Certain other codes require customer passwords. The majority of logged codes do not require passwords

to be cleared. To obtain factory passwords, proceed as if you already have the password. At some point, if the

factory passwords are actually needed, TIPSS-EST will request the factory passwords and display the

information required to obtain the passwords.

Customer passwords

If customer passwords have been entered, they are then required to change ANY customer parameter.

TIPSS-EST can be used to change customer parameters. To obtain customer passwords, contact the supplier

of the equipment. If the owner has lost the passwords, customer passwords may be read by using TIPSS-EST

(factory passwords are required in order to read customer passwords) by using the following procedure.

1 In TIPSS-EST access "Passwords" under the "Information" menu.

2 When the "Factory Password" screen appears, record the information listed.

3 Obtain the factory passwords. The information recorded above must be provided, and generates a

permanent record at Perkins of the access.

4 From the "Factory Password" screen, enter the factory passwords.

5 When the "View Customer Passwords" screen appears, record the customer passwords. The customer

passwords may then be used to change customer parameters.

Diagnostic Manual, TSD 3457E, Issue 2

23

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

3

2300 Series

Programming a new ECM

The Engine Control Module or ECM is the brain of the system. When a problem occurs, it is easy to assume

that the ECM is responsible. This is usually the wrong conclusion.

Most failures occur at the wiring and connectors or at a sensor input/output. Follow the diagnostic test

procedures and do not replace an ECM on speculation.

However, when your diagnosis indicates that a failure has in fact occurred in the ECM, the following procedure

outlines the steps required to replace a faulty ECM.

Note: If an ECM replacement is required, the ECM parameters and injector trim codes can be transferred from

the suspect ECM to the replacement ECM. This feature requires TIPSS-EST and is only possible if the suspect

ECM can communicate with the TIPSS-EST.

Replacing the ECM using TIPSS-EST ECM replacement feature

Note: The Test ECM referred to below is another identical ECM to that fitted to the engine. There is no special

Test ECM available.

1 Ensure that the ECM is the problem by first temporarily connecting a test ECM. Hang the test ECM on the

side of the engine. Flash program the identical software that was used in the suspect ECM into the test ECM.

Use the TIPSS-EST ECM replacement feature to copy the parameter configuration of the suspect ECM into

the test ECM. Ensure that the parameters in the test ECM are programmed the same as the parameters in the

suspect one.

2 If the test ECM repairs the problem, reconnect the suspect ECM. Check that the problem returns when the

suspect ECM is reconnected.

3 Select the ECM Replacement feature under the "Service/Copy Configuration" menu and load the

parameters from the failed ECM.

4 Temporarily connect the new ECM by connecting both ECM connectors. Do not mount the ECM on the

engine yet.

5 Flash program the ECM software into the new ECM if the software is not already installed.

Note: The new ECM may be shipped with no software installed or may have been pre-flashed at the factory.

Following reflashing the engine may be inoperable until a factory password has been obtained.

6 Use the TIPSS-EST ECM replacement feature to program the new ECM

7 Enter rating number parameter into the new ECM

8 Check for active codes. Program any required parameters that have not been programmed.

Note: On initial power-up of a new ECM, the Rating Number parameter must be programmed to avoid a

268-02 Check Programmable Parameters diagnostic code.

Install the new ECM on the engine and after checking for correct operation perform a timing calibration.

24

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

3

2300 Series

Replacing the ECM (if ECM replacement feature cannot be used)

1 Ensure that the ECM is the problem by first temporarily connecting a test ECM. Hang the test ECM on the

side of the engine. Flash program the identical software that was used in the suspect ECM into the test ECM.

Program any parameters that are necessary to use the ECM for the test. Program the parameters exactly the

same as they are in the suspect ECM.

2 If the test ECM repairs the problem, reconnect the suspect ECM. Check that the problem returns when the

suspect ECM is reconnected.

3 Obtain customer parameters from the failed ECM

Obtain and record the customer passwords. If the customer has lost or forgotten their passwords, obtain

factory passwords to get them.

Use TIPSS-EST to access customer specified parameters from the ECM that is being replaced. If the ECM

does not communicate with the electronic service tool, obtain the required parameter list from the OEM.

Record the customer parameters.

4 Record ECM current totals

5 Temporarily connect the new ECM by connecting both ECM connectors. Do not mount the ECM to the

engine until the timing calibration has been performed.

6 Flash program the software into the new ECM if the software is not already installed.

Note: The new ECM may be shipped with no software installed, or may have been pre-flashed at the factory.

7 Obtain factory passwords if required. The following parameters can be programmed once on a new ECM

without factory passwords:

Full Load Setting (FLS)

Full Torque Setting (FTS)

Engine serial number

System configuration parameters must be entered before the customer specified parameters are entered

If customer parameters are entered before the system configuration parameters, the total tattletale will change.

It will then be necessary to obtain another set of factory passwords in order to access system configuration

parameters.

8 Record the following information from the engine information plate:

Engine serial number

Obtain the following information from the factory:

Full Load Setting (FLS)

Full Torque Setting (FTS)

Injector Trim Codes

Use TIPSS-EST to access system configuration parameters. When the "Factory Specified Passwords" screen

appears record the following information:

ECM serial number

Engine serial number

TIPSS-EST serial number

Total tattletale

Reason code

Leave TIPSS-EST on the "Factory Specified Passwords" screen and obtain the factory passwords.

Continued

Diagnostic Manual, TSD 3457E, Issue 2

25

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

2300 Series

9 Program the new ECM

On initial powerup of a new ECM the following three parameters must be programmed to avoid a 268-02

Check Programmable Parameters diagnostic code:

Full Load Setting (FLS)

Full Torque Setting (FTS)

Engine serial number

Use TIPSS-EST to access system configuration parameters. Enter the recorded values for the following

parameters:

Full Load Setting (FLS)

Full Torque Setting (FTS)

Engine serial number

Injector trim codes

Use TIPSS-EST to access customer specified parameters. Enter the customer specified parameters and the

original customer passwords.

Use TIPSS-EST to access current totals from the "Read/Change Current Totals" main menu. Using the

recorded factory passwords enter the totals from the original ECM.

Use the "Service\Calibrations\Timing Calibration" menu to calibrate the timing. Refer to Test 46: Engine

speed/timing circuit test on page 126.

10 Install the new ECM on the engine.

26

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

2300 Series

Programming an ECM using flash programming

1 Connect the PC to the appropriate communication adapter and connect the communication adapter to the

ECM. Refer to "Connecting TIPSS-EST using a TIPSS communication adapter" on page 22.

2 Start the WinFlash PC Program.

3 Ensure that the key switch is ON and the engine is OFF.

4 Select the part number of the engine software that needs to be programmed into the ECM and proceed with

programming. A new ECM is shipped with no software loaded.

Note: The WinFlash PC program provides the ECM, application and software part number of the selected file.

Ensure that this file matches the engine before you begin to Flash the file into the ECM

PC program software messages and their meaning

A new ECM comes unprogrammed. An unprogrammed ECM will prompt you for all three of the following

messages. The information that is contained in the ECM Status will be scrambled and meaningless if the

module has not been programmed previously (this is normal).

Message: The engine ID in the flash file does not match the engine ID in the ECM

Meaning: The ECM has software for a different engine.

Solution: Stop the transfer and access information about the ECM Status under the "Electronic Control

Module" menu. Ensure that the file you are about to transfer matches the engine application.

Message: The application ID in the flash file does not match the application ID in the ECM

Meaning: The ECM has software for a different application.

Solution: Stop the transfer and access information about the ECM Status under the "Electronic Control

Module" menu. Ensure that the file you are about to transfer is for the correct engine type.

Message: The ID of the ECM in the flash file does not match the ID of the ECM in the ECM

Meaning: The ECM is not for use with this application.

Solution: Stop the transfer and access information about the ECM status under the "Electronic Control

Module" menu. Ensure that the ECM on the engine is for the correct application.

Note: If you access the ECM status under the "Engine Control Module" menu, but do not program the ECM,

complete the following procedure.

Turn the key switch to the OFF position, and then to the ON position before using TIPSS-EST. If the key switch

is not cycled after reading the ECM Status, the ECM will not communicate with your service tool or will not start.

Cycling the key switch is not necessary after the software has been successfully programmed using the

WinFlash program.

5 Start the engine and check for correct operation.

Program any parameters not previously in the old software if a 268-02 Check Programmable Parameters

diagnostic code is active. Read the diagnostic code from service tool "Active Diagnostic Code" screen in order

to determine the parameter(s) requiring programming.

On initial powerup of a new ECM three parameters must be programmed to avoid a 268-02 Check

Programmable Parameters diagnostic code:

Full Load Setting (FLS)

Full Torque Setting (FTS)

Engine serial number

Refer to "Programming a new ECM" on page 24.

Diagnostic Manual, TSD 3457E, Issue 2

27

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

3

2300 Series

ECM date/time clock

ECM date/time stamped information

The ECM date and time can be programmed with the TIPSS-EST service tool (factory passwords are required

to change these parameters). This will display the programmed date in month/day/year format and the

programmed time in hour:minute:second format. The tool has the option to program any date/time or

automatically select the date/time stored in the PC real time clock.

The date and time will remain programmed in the ECM even if the unswitched battery connections are

removed.

The ECM Date/time clock is used to stamp the following critical event codes:

360-3 Low oil pressure Shutdown

361-3 High coolant temperature Shutdown

Before adjusting the ECM date/time clock

Before adjusting the ECM date/time clock, ask the owner/operator if the time stamped information should be

recorded. After the time stamped information is recorded, clear this information before adjusting the ECM date/

time clock. This is a very important step if the adjustment of the clock is a big adjustment. This will prevent

unnecessary confusion if someone else views the information at a later date.

Determining time stamped information occurrence

When viewing time stamped information remember that someone may have incorrectly or never set the clock.

Use the time currently set in the ECM to compare any ECM recorded information to the time the ECM indicates

to determine how long ago the time stamped event occurred.

Caution: Do not replace an ECM because of an incorrect time.

The following example indicates the correct use of the clock.

Example use of ECM date/time stamped information

The TIPSS-EST service tool indicates a Low Oil Pressure occurred on NOV 19 1998 10:30:46 and that the

current time of day in the ECM is NOV 24 1998 11:20:58.

This indicates that the problem occurred approximately 5 days and 50 minutes ago.

Caution: Do not compare it to the current time at your location.

If the ECM time is significantly different than your current time, for example the wrong month is programmed,

ensure you have recorded the time stamped information if it is important. After recording the information, clear

the code and then adjust the clock.

28

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

3

2300 Series

ECM diagnostic clock

The diagnostic clock should not be confused with the ECM date/time clock. The diagnostic clock records the

actual hours the ECM has been powered (key switch ON and engine running). This information is maintained

even if the unswitched battery connections are removed. The clock information is used to log diagnostic code

and event code occurrences. Logged diagnostic codes and event codes display the diagnostic clock hour of

the first and last occurrence and the total number of occurrences.

Note: Actual engine running hours (total time) can be obtained from the "Current Totals" menu of TIPSS-EST.

Injector codes

Injector codes are etched on each injector. The injector codes can be viewed/changed using TIPSS-EST by

selecting the "Calibrations" screen under the "Service" menu. The injector codes calibration is located under

the "Calibration" menu. The injector code must match the code on the corresponding injector. When an injector

is replaced, reprogram the new code for the new injector.

TIPSS-EST cylinder cut-out test

The 2300 and 2800 Series engines use electronic fuel injectors. These injectors are mechanically actuated

and electronically energized. The cylinder cut-out tests are used to confirm that the cylinders are functioning

correctly.

The cylinder cut-out test allows a specific cylinder to be cut out while the fuel position is monitored for the

remaining cylinders.

To perform a cylinder cut-out test, connect TIPSS-EST to the diagnostic connector as described in

"Connecting the TIPSS-EST" on page 21, and select the Cylinder cut-out test located under the "Diagnostics"

menu.

The Cylinder cut-out test opens with the manual test. At the bottom of the TIPSS-EST screen there is a row of

buttons that function as follows:

Change toggles the highlighted cylinder between powered and not powered

Power All returns all cylinders to the normal operating state

Start initiates the automated Cylinder cut-out test.

Stop terminates the automated test.

Results displays the test results.

Print allows the contents of the screen to be previewed or to be sent to a file or printer.

Programming parameters

Many programmable parameters affect engine operation. These parameters may be changed by using the

TIPSS-EST service tool. The parameters are stored in the ECM. Whilst any parameter can be read, passwords

can be used to protect parameters from unauthorized changes.

Two categories contain these various parameters:

System configuration parameters

System configuration parameters can only be altered with factory passwords by using TIPSS-EST.

Customer specified parameters

Customer specified parameters can be changed by using the TIPSS-EST service tool (this may require

customer passwords if customer passwords have been programmed). Refer to "Passwords" on page 13 for

more details on how to receive and use factory and customer passwords.

Diagnostic Manual, TSD 3457E, Issue 2

29

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

3

2300 Series

System configuration parameters

System configuration parameters affect critical settings for the engine. They are programmed at the factory

and would normally never need to be changed through the life of the engine. A complete list of these

parameters is given in the table on the following page.

Note: System Configuration Parameters must be reprogrammed if an ECM is replaced. Failure to programme

these parameters will result in a 268-02 Check Programmable Parameters diagnostic code.

Proper values for these parameters are stamped on the engine information ratings plate located on the valve

cover or air inlet manifold. Factory passwords are required to change these parameters. The following

information is a description of the system configuration parameters.

Full Load Setting (FLS)

Number representing fuel system adjustment made at the factory to “fine tune” the fuel system. The correct

value for this parameter is stamped on the engine information ratings plate. A new ECM requires this

parameter to be programmed to avoid generating a 268-02 Check Programmable Parameters diagnostic code.

Full Torque Setting (FTS)

Similar to Full Load Setting. This parameter must be programmed to avoid generating a 268-02 Check

Programmable Parameters diagnostic code.

Software part number

This is the part number of the software flashed into the ECM.

Engine serial number

This should be programmed to match the engine serial number that is stamped on the engine information plate.

A new ECM is delivered without the engine serial number programmed.

ECM serial number

This is a read-only parameter which displays the serial number of the ECM.

Software release date

This parameter is defined by the ECM software and is not programmable. It is used to provide the version of

the software. Customer parameters software changes can be tracked by this date. The date is provided in the

month and year (NOV99), where NOV is the month (November) and 99 is the year (1999).

Critical override switch installed

The critical override switch, if fitted and enabled, allows the engine to continue running even if engine oil

pressure or coolant temperature have reached the limits where the engine would normally be shutdown. If the

engine is run in this condition, the engine warranty is void and any events occurring are stored in the ECM with

time and date stamping. Implementation of this facility requires a factory password.

Total tattletale

Displays the total number of times the configuration parameters have been changed.

30

Diagnostic Manual, TSD 3457E, Issue 2

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

3

2300 Series

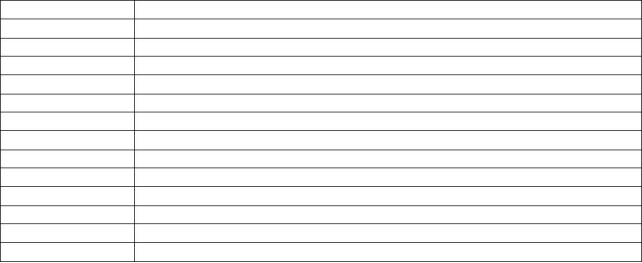

Configuration parameters

Configuration Parameter Description

R/W Security

Selected Engine Rating

Rating Number

Customer

Rated Frequency

Read Only

Read Only

Read Only

Read Only

Read Only

Customer

Rated Genset Speed

Rated Real Genset Power

Rated Apparent Genset Power

Engine Rating Application Type

External Speed Selection Switch Installed

ECM Identification Parameters

Equipment ID

Customer

Factory

Engine Serial Number

ECM Serial Number

Read Only

Read Only

Read Only

Read Only

ECM Software Part Number

ECM Software Release Date

ECM Software Description

Security Access Parameters

Total Tattletale

Read Only

Engine/Gear Parameters

Engine Acceleration. Rate

Droop/Isochronous Switch Installed

Droop/Isochronous Selection

Engine Speed Droop

Customer

Customer

Customer

Customer

Factory

Critical Override Switch Installed

Digital Speed Control Installed

Speed Control Min Speed

Speed Control Max Speed

Digital Speed Control Ramp Rate

Crank Terminate Speed

I/O Configuration Parameters

Desired speed Arrangement

System Parameters

Customer

Customer

Customer

Customer

Customer

Customer

FLS

Factory

Factory

None

FTS

Governor ProportionalGain

Governor Minimum Stability Factor

Governor Maximum Stability Factor

Passwords

None

None

Customer Password 1

Customer

Customer

Customer Password 2

Diagnostic Manual, TSD 3457E, Issue 2

31

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

3

2300 Series

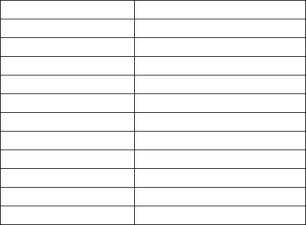

Customer specified parameters

Customer specified parameters allow the OEM to modify engine parameters to suit the application.

Customer parameters may be changed repeatedly as a customer changes his requirements. Customer

passwords are required to change these parameters.

The following information is a brief description of the customer specified parameters.

Rating duty selection

This enables selection of the engine rating from a series of maps within the ECM. Changing the rating requires